- Client:

- Engineering Contractor:

- Date of Award:

- Scope of Work:

- Offshore Industries (SAFF) Co.

- Saff Rosemond

- 2010

- Basic & Detail Design & Patent Licensing

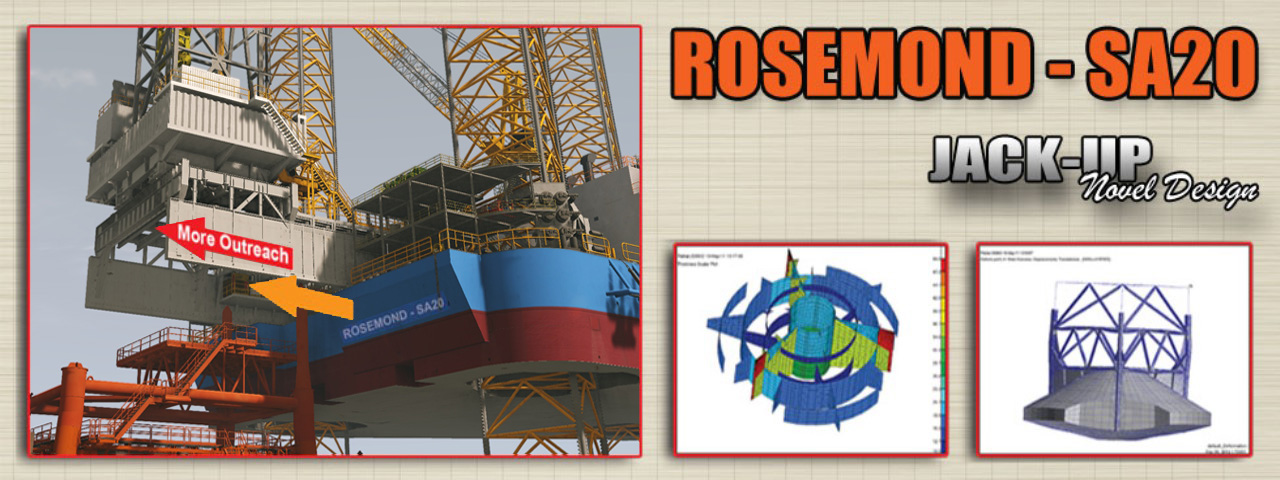

ROSEMOND-SA20 has been designed by Saff Rosemond Engineering & Management Company and has been registered as a Novel Design and all its proprietary rights are reserved for Saff-Rosemond Engineering & Management Company. The complete package of principal engineering documents/drawings (including basic and detail design) have been verified by authorized international Classification Society (i.e. IACS members) and are deliverable to National/International Clients on request.

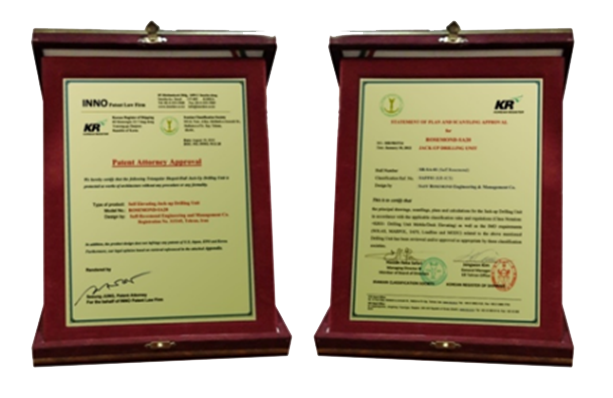

ROSEMOND-SA20 design has been awarded by a number of National/International authorities. Some of the obtained Certificates/Awards are:

- Certificate of Design Compliance with international Rules & Regulations from �Korean Register of Shipping� (KR) & �Iranian Classification Society� (ICS)

- Certificate of Technological Proficiency for development of ROSEMOND SA-20 Jack Up Design from IROST

- �Petroleum and Natural Gas Industries - Specific Assessment of Mobile Offshore Units� ISO 19905-1:2012; as the first in this scope in Iran, Certified by EuroCert

- Appreciation award for localization of Design of Offshore Drilling Rig in 14th annual seminar of IMES

- Appreciation award in the 3rd& 4th annual seminar of Growth of Local Capabilities

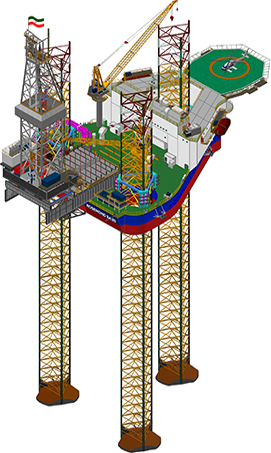

- Operating water depth

- Drilling depth

- Length overall

- Width overall

- Depth of hull

- Leg total length

- Leg distance (Transversal)

- Leg distance (Longitudinal)

- Spud can Diameter

- Max drill floor offset

- Max variable load deck load

- Max survival deck load

- Max combined drill floor load

- 330 ft. (100.58 m)

- 30000 ft. (9144 m)

- 196.5 ft.

- 177 ft.

- 25 ft.

- 441 ft.

- 115 ft.

- 120.08 ft.

- 46.26 ft. (14.1m)

- �15 ft.

- 9000 kips

- 6000 kips

- 2200 kips

- Ample free space on main deck for convenient operation

- Optimization space utilization in arrangement design

- Consideration of easy maintenance

Developing new technique for quantitative study of Risk and computation of dependability parameters

- Over 1800 m2 Accommodation area

- Comfortable and Modern furniture

- 120 men capacity

- Noticeable quantity of 1 & 2 men cabins

- Less penetration due to increased load bearing surface of spud cans

- Innovative solution for Larger Spud Can design without losing deck space

- Approval design analysis by international authorities

- 60ft X 30ft drilling pattern

- Maximum combination load of drill floor: 2200 kips

- Maximum tolerable load of cantilever pipe rack: 1100 kips

- Producing Construction sequence in line with local facilities

- Creative procedure for leg assembly and hull launching